Defects of Overmolded Lampshades

On this page

The lampshade injection overmolding process is widely used in the fields of automobiles, home appliances, and electronic products, offering advantages such as high production efficiency, low cost, and an attractive product appearance. However, in the actual production process, plastic overmolding parts often faces various defects, including air entrapment, warping, flash, color discontinuity, short shots, and color mixing, which directly affect the light transmittance, appearance quality, and assembly accuracy of the lampshades. Among these, quality defects such as color discontinuity and gas entrapment can be addressed by modifying the product and mold design and adjusting process parameters. However, warping is challenging to avoid. Warping deformation is particularly noticeable in two-color thin-walled parts. Unlike traditional single-color injection molding, the first and second shots in plastic overmolding interact with and influence each other, resulting in residual stress and uneven shrinkage at the junction of the two-color interface, which causes warping in plastic injection overmolding parts. In overmolding injection molding, the reliability of the bonding surface is directly related to the product’s service life and appearance quality. If the bonding performance between the two melts is poor or if the process parameters are not properly set, cracking, peeling, and color mixing may occur during product use. This article analyzes common defects in lampshade injection molding, their causes, and proposes corresponding solutions.

I. Common Overmolding Defects and Causes

Color Difference

Definition: There is an obvious color difference at the jointing part of the overmolding lampshade, which affects the appearance quality of the product.

Causes:

The temperature control of the injection molding machine is unstable, resulting in different melting states of plastics of different colors.

Uneven mold temperature leads to uneven color distribution.

Uneven distribution of pigments in the raw materials.

Unstable injection pressure and speed affect the fluidity of the plastic molded part.

Uneven mold temperature leads to uneven color distribution.

Uneven distribution of pigments in the raw materials.

Unstable injection pressure and speed affect the fluidity of the plastic molded part.

Color Discontinuity

Definition: Color discontinuity refers specifically to the visible boundary or transition line where different colors meet, often at the joint or interface between two molded areas. This defect manifests as an abrupt or noticeable change in color, disrupting the visual uniformity of the product.

Causes:

Lack of proper bonding between different layers or materials.

Variations in processing conditions that affect color consistency at the interface.

Differences in the chemical or physical properties of the materials that affect color appearance.

Causes:

Lack of proper bonding between different layers or materials.

Variations in processing conditions that affect color consistency at the interface.

Differences in the chemical or physical properties of the materials that affect color appearance.

Gas Entrapment

Definition: Gas entrapment occurs when air or gases become trapped inside the molded part during the injection process. These trapped gases can create visible bubbles or voids within the material, impacting both the transparency and appearance of the final product.

Causes:

Air is not completely discharged during the injection molding process.

The mold temperature is too low, causing the plastic to cool too quickly and preventing the gas from being discharged.

The water content of the plastic raw material is too high, leading to bubbles generated by the evaporation of water during injection molding.

High injection pressure can force air into the mold cavity, which contributes to bubble formation.

Causes:

Air is not completely discharged during the injection molding process.

The mold temperature is too low, causing the plastic to cool too quickly and preventing the gas from being discharged.

The water content of the plastic raw material is too high, leading to bubbles generated by the evaporation of water during injection molding.

High injection pressure can force air into the mold cavity, which contributes to bubble formation.

Voids or Cavitation

Description: These are empty spaces or cavities within the molded part that can occur either on the surface or internally. They often result from incomplete filling of the mold, trapped air, or gas generation during the molding process.

Impacts

Structural Strength: Voids or internal cavities can significantly reduce the structural integrity of the lampshade, making it more prone to breakage or deformation under stress.

Appearance: Surface depressions and internal cavities negatively impact the aesthetic quality of the product, leading to a poor finish and visible defects on the lampshade.

Causes:

Insufficient injection pressure leads to incomplete filling.

If the injection speed is too slow, it can cause premature cooling or solidification of the material before the mold cavity is completely filled.

Inadequate venting in the mold design can trap air or gases, leading to voids as the air gets trapped and forms bubbles inside the part.

Air or gas can be entrapped during the injection process if the mold is not properly vented or if the injection process is not optimized.

Excessive melt temperature can lead to gas evolution and insufficient material flow, causing voids as the gas escapes during cooling.

Impacts

Structural Strength: Voids or internal cavities can significantly reduce the structural integrity of the lampshade, making it more prone to breakage or deformation under stress.

Appearance: Surface depressions and internal cavities negatively impact the aesthetic quality of the product, leading to a poor finish and visible defects on the lampshade.

Causes:

Insufficient injection pressure leads to incomplete filling.

If the injection speed is too slow, it can cause premature cooling or solidification of the material before the mold cavity is completely filled.

Inadequate venting in the mold design can trap air or gases, leading to voids as the air gets trapped and forms bubbles inside the part.

Air or gas can be entrapped during the injection process if the mold is not properly vented or if the injection process is not optimized.

Excessive melt temperature can lead to gas evolution and insufficient material flow, causing voids as the gas escapes during cooling.

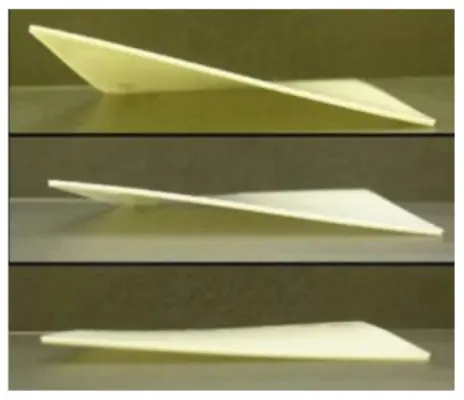

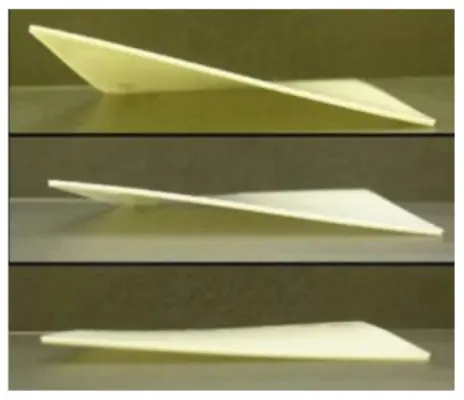

Warping

Definition: The colored lampshade warps or deforms after molding, affecting its assembly and use.

Causes:

The cooling shrinkage rates of the two plastics differ.

Uneven mold temperature distribution results in inconsistent cooling.

Unreasonable parameter settings on the injection molding machine, combined with excessively high injection pressure or speed, contribute to the problem.

Causes:

The cooling shrinkage rates of the two plastics differ.

Uneven mold temperature distribution results in inconsistent cooling.

Unreasonable parameter settings on the injection molding machine, combined with excessively high injection pressure or speed, contribute to the problem.

Short Shot

Definition: This occurs when the molten plastic fails to completely fill the mold cavity during the injection molding process, leading to incomplete or defective products. The product may have missing sections, incomplete features, or visible gaps. It affects the product's functionality, appearance, and structural integrity. The short shot may be manifested as follows:

- Unfilled areas may appear on the surface or inside the lampshade.

- There may be uneven color, especially at the color boundary, with obvious defects.

- The shape of the lampshade may be incomplete, with missing edges or parts.

Causes: The main causes of short shots in the overmolding lampshade injection molding process are improper injection molding process parameter settings (insufficient injection molding pressure, too slow injection molding speed, too low melt temperature, too low mold temperature), mold design problems (unreasonable runner design, insufficient gate location and number, imperfect exhaust system), material problems (poor material fluidity, high material water content), equipment problems (poor performance of the injection molding machine, mold surface problems), and process control problems (unstable process control, insufficient operator experience).

Color Mixing

Definition: Color mixing refers to the phenomenon where two different colors of plastics are inappropriately mixed on the product during the overmolding process, resulting in impure or mixed colors on the product surface. Color mixing may be manifested as follows:

- Areas with mixed colors may appear on the surface of the lampshade.

- There may be blurred boundaries between the two colors and unclear color transitions.

- Uneven mixed colors or spots may appear at the color boundary.

Flash

Definition: Flash occurs when excess plastic material escapes from the mold cavity through gaps at the parting line, gates, or other openings during the injection molding process. This results in thin, excess material forming around the edges of the molded part, which affects both the appearance and functionality of the final product. Flash may manifest as follows:

- Thin plastic edges appear at the edge, seam, or gate positions of the lampshade.

- Flash may cover the surface of the product, affecting its appearance and feel.

- Flash needs to be removed through subsequent processing, which increases production costs and process complexity.

2. Solutions

(1) Controlling the temperature of the injection molding machine

Regularly calibrate the temperature control system of the injection molding machine to ensure stable temperatures. Set the temperature of the injection molding machine and mold according to the characteristics of different plastics.

(2) Optimizing mold design

During the mold design stage, fully consider the characteristics of overmolding injection molding and design the flow channels and cooling system accordingly. Ensure uniform temperature at the mold joints to avoid color differences and seam line problems caused by uneven cooling.

(3) Improving raw material processing

Use plastic raw materials with stable quality and uniform color distribution. Thoroughly dry the plastic raw materials to reduce moisture content and avoid bubbles.

(4) Adjusting injection molding parameters

Set the injection molding pressure and speed appropriately to ensure uniform plastic filling. Adjust the injection molding cycle according to the product structure and mold design to ensure that the plastic is fully cooled.

(5) Strengthening quality monitoring

Establish a comprehensive quality control system to monitor and adjust various parameters in the production process in real time. Inspect the molded products rigorously to detect and address molding defects in a timely manner.

3. Conclusion

In the lampshade overmolding process, the formation of defects results from the combined action of multiple factors. By optimizing mold design, setting injection molding parameters appropriately, improving raw material processing, and strengthening quality monitoring, molding defects can be effectively reduced and product quality improved. In the future, as injection molding technology develops and processes continue to improve, overmolding will be applied in more fields, contributing to the advancement and evolution of the manufacturing industry.

Related News

- Design of Two-stage Overmolding for Automobile Headlight Cover

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part Two)

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part one)

- Design of the Upper Cover of a Household Air Conditioner Remote Control

- The Mold Cavity of Overmolding Handheld Forehead Thermometer Casing

- Overmolding Handheld Forehead Thermometer Shells

- Defects of Overmolded Lampshades

- An Introduction to Overmolding

- Overmolding Lampshades For Car Headlights

- Deformation of Plastic Components

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.