Deformation of Plastic Components

Deformation of plastic components is a common problem in industrial production and daily use, affecting their appearance, dimensional accuracy, and functional performance.

Impact of Deformation on Plastic Components

Deformation of plastic components can have many effects on products, including but not limited to the following:

(1) Degradation of Dimensional Accuracy and Appearance Quality

Excessive shrink or internal stress of plastic components during the injection molding process leads to shape deformation, reduced dimensional accuracy of the final product, and unsatisfactory appearance quality, affecting the product's aesthetics and market competitiveness.

(2) Degradation of Mechanical Properties

The deformation of plastic components may cause internal structural instability or stress concentration, affecting their mechanical properties, such as strength, wear resistance, and durability, thereby shortening the service life of the product.

(3) Impaired Functions

Some plastic components require precise sizes and shapes to ensure their functions in specific engineering applications. Once deformed, they may lose their sealing, electrical insulation, and fluid control ability, thus affecting the overall function and safety of the product.

(4) Increased Production Costs

Deformation of plastic components increases the defect rate of production batches, resulting in scrap and rework costs, increasing the time cost of production line adjustment and maintenance, thereby increasing the overall production cost.

Types of Deformation of Plastic Components

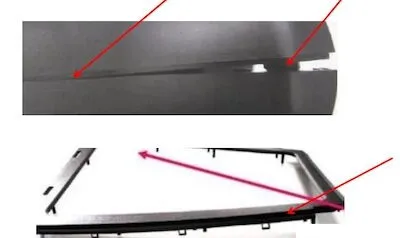

Common types of deformation of plastic components include warping, shrinkage, bending, and stress cracking. Warping is usually caused by uneven cooling or internal stress, resulting in irregular bending of the plastic part partially or as a whole. Shrinkage occurs when the plastic part’s volume decreases during the cooling process, resulting in a decrease in dimensional accuracy. The plastic part bends partially or totally when stored or used under stress, affecting its normal use and appearance. Stress cracking is caused by internal stress concentration during manufacturing or use, leading to cracks or even fractures in the plastic, which reduces its structural strength and durability.

Causes of Deformation of Plastic Components

(1) Improper Temperature Control

Temperature control is crucial during the injection molding process. Improper temperature control leads to uneven temperatures inside the plastic part. Uneven temperatures causes the plastic material to shrink inconsistently during the cooling process, thus causing deformation. For example, if the injection temperature is too high, the surface of the plastic part will be overheated, while the internal cooling will be slow, forming a temperature difference between the inside and the outside; conversely, if the injection temperature is too low, the plastic part will cool too quickly in the mold, making it prone to stress concentration.

(2) Unreasonable Mold Design

The mold design directly affects the quality and dimensional accuracy of plastic components. Unreasonable mold design is one of the important reasons for deformed plastic components. For example, improper positions of the feed port cause uneven flow of plastics in the mold cavity, resulting in uneven shrinkage and deformation. In addition, an unreasonable design of the mold cooling system also causes uneven cooling of plastic components, causing deformation. Poor injection process parameters, such as improper injection speed and pressure control, also affect the quality of plastic components.

(3) Uneven Materials

The plastic’s uniformity is crucial to the forming quality of plastic components. If the plastic used is uneven, the material will shrink inconsistently during the cooling process, causing deformation. For example, mixed materials from different batches or impurities in the materials cause uneven shrinkage of plastic components during the molding process. In addition, the physical properties of the material itself, such as molecular weight distribution and crystallinity, also affect the forming quality of plastic components.

(4) Short of Materials

When the material fails to completely fill the mold cavity during the injection molding process, it will cause defects such as bubbles and shrinkage holes, affecting the structure and strength of the plastic part and making the material easily deformed during cooling and use. Material shortage is usually caused by insufficient injection pressure, excessively slow injection speed, or unreasonable mold design.

(5) Unstandardized Operation Technology

The operator’s technical level and experience in the injection molding process have a significant influence on the quality of plastic components. If the operation is improper, such as excessively fast or slow filling speed and insufficient holding time, excessive internal stress or structural instability of the plastic part will occur, causing deformation of the plastic part.

In addition to the above reasons, some other factors can also cause plastic components to deform, such as mold wear, excessive or insufficient injection pressure, and insufficient cooling time.

Solutions

To solve the problem of plastic components deformation, the following measures can be taken:

Types of Deformation of Plastic Components

Common types of deformation of plastic components include warping, shrinkage, bending, and stress cracking. Warping is usually caused by uneven cooling or internal stress, resulting in irregular bending of the plastic part partially or as a whole. Shrinkage occurs when the plastic part’s volume decreases during the cooling process, resulting in a decrease in dimensional accuracy. The plastic part bends partially or totally when stored or used under stress, affecting its normal use and appearance. Stress cracking is caused by internal stress concentration during manufacturing or use, leading to cracks or even fractures in the plastic, which reduces its structural strength and durability.

Causes of Deformation of Plastic Components

(1) Improper Temperature Control

Temperature control is crucial during the injection molding process. Improper temperature control leads to uneven temperatures inside the plastic part. Uneven temperatures causes the plastic material to shrink inconsistently during the cooling process, thus causing deformation. For example, if the injection temperature is too high, the surface of the plastic part will be overheated, while the internal cooling will be slow, forming a temperature difference between the inside and the outside; conversely, if the injection temperature is too low, the plastic part will cool too quickly in the mold, making it prone to stress concentration.

(2) Unreasonable Mold Design

The mold design directly affects the quality and dimensional accuracy of plastic components. Unreasonable mold design is one of the important reasons for deformed plastic components. For example, improper positions of the feed port cause uneven flow of plastics in the mold cavity, resulting in uneven shrinkage and deformation. In addition, an unreasonable design of the mold cooling system also causes uneven cooling of plastic components, causing deformation. Poor injection process parameters, such as improper injection speed and pressure control, also affect the quality of plastic components.

(3) Uneven Materials

The plastic’s uniformity is crucial to the forming quality of plastic components. If the plastic used is uneven, the material will shrink inconsistently during the cooling process, causing deformation. For example, mixed materials from different batches or impurities in the materials cause uneven shrinkage of plastic components during the molding process. In addition, the physical properties of the material itself, such as molecular weight distribution and crystallinity, also affect the forming quality of plastic components.

(4) Short of Materials

When the material fails to completely fill the mold cavity during the injection molding process, it will cause defects such as bubbles and shrinkage holes, affecting the structure and strength of the plastic part and making the material easily deformed during cooling and use. Material shortage is usually caused by insufficient injection pressure, excessively slow injection speed, or unreasonable mold design.

(5) Unstandardized Operation Technology

The operator’s technical level and experience in the injection molding process have a significant influence on the quality of plastic components. If the operation is improper, such as excessively fast or slow filling speed and insufficient holding time, excessive internal stress or structural instability of the plastic part will occur, causing deformation of the plastic part.

In addition to the above reasons, some other factors can also cause plastic components to deform, such as mold wear, excessive or insufficient injection pressure, and insufficient cooling time.

Solutions

To solve the problem of plastic components deformation, the following measures can be taken:

(1) Optimization of Temperature Control

Precisely control the injection temperature to ensure that the plastic is in a good molten state and has good flow properties during the injection process. Set cooling time and speed reasonably. Avoid demolding too early or too late. Ensure uniform temperature inside and on the surface of the plastic components, reducing internal stress.

(2) Improvement of Mold Design

Optimize the design of feed ports and runners. Ensure uniform flow during plastic filling, reducing uneven shrinkage and deformation. Improve the cooling system. Design a reasonable cooling water channel layout; control the cooling rate; uniformly cool the plastic components, and reduce internal stress and deformation. Optimize injection process parameters, such as injection speed, pressure, and holding time to ensure that the plastic is filled and gaps and material shortages are reduced.

(3) Material Selection and Quality Control

Use high-quality and uniform plastics. Regularly test and evaluate the physical properties of materials, such as molecular weight and crystallinity, to ensure the stability and durability of plastic components.

(4) Standardizing Operation

Improve the operator’s technical level and training. Regular professional training is provided to operators to enable them to master the basic principles and operation skills of injection molding process. Arrange for experienced technicians or engineers to guide new operators on-site. Correct errors in operation in a timely manner, and impart skills and experience in actual production.

Conclusion

Deformation of plastic parts is a complex problem involving multiple factors such as material properties, mold design, the injection molding process, and environmental conditions. By optimizing material selection, rationally designing molds, optimizing injection molding processes, and controlling environmental conditions, deformation of plastic parts can be effectively prevented and solved, thereby improving product quality and production efficiency. In actual production, appropriate measures should be taken according to specific circumstances to ensure the dimensional accuracy and functional performance of plastic components.

Conclusion

Deformation of plastic parts is a complex problem involving multiple factors such as material properties, mold design, the injection molding process, and environmental conditions. By optimizing material selection, rationally designing molds, optimizing injection molding processes, and controlling environmental conditions, deformation of plastic parts can be effectively prevented and solved, thereby improving product quality and production efficiency. In actual production, appropriate measures should be taken according to specific circumstances to ensure the dimensional accuracy and functional performance of plastic components.

Related News

- Design of Two-stage Overmolding for Automobile Headlight Cover

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part Two)

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part one)

- Design of the Upper Cover of a Household Air Conditioner Remote Control

- The Mold Cavity of Overmolding Handheld Forehead Thermometer Casing

- Overmolding Handheld Forehead Thermometer Shells

- Defects of Overmolded Lampshades

- An Introduction to Overmolding

- Overmolding Lampshades For Car Headlights

- Deformation of Plastic Components

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.