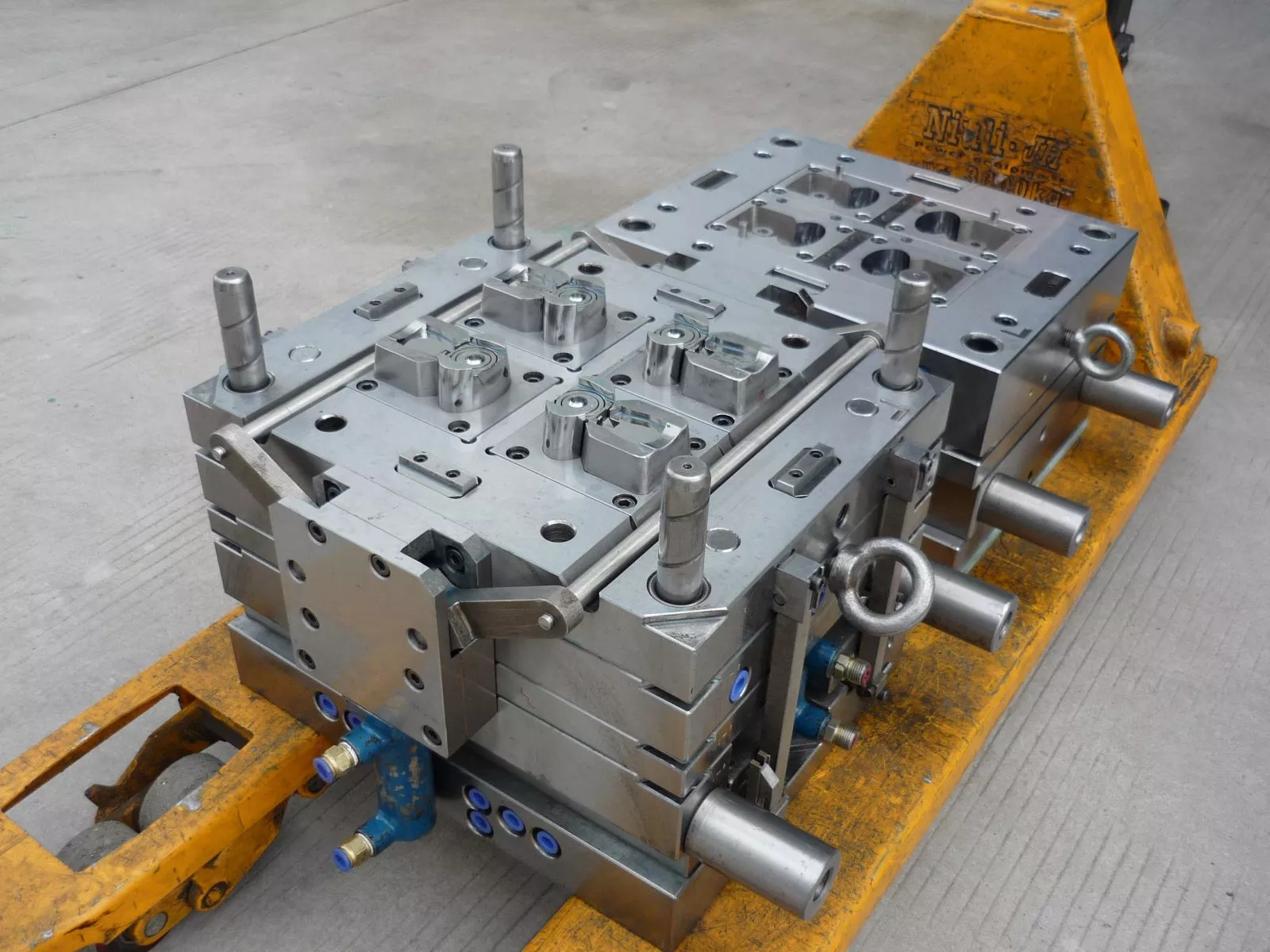

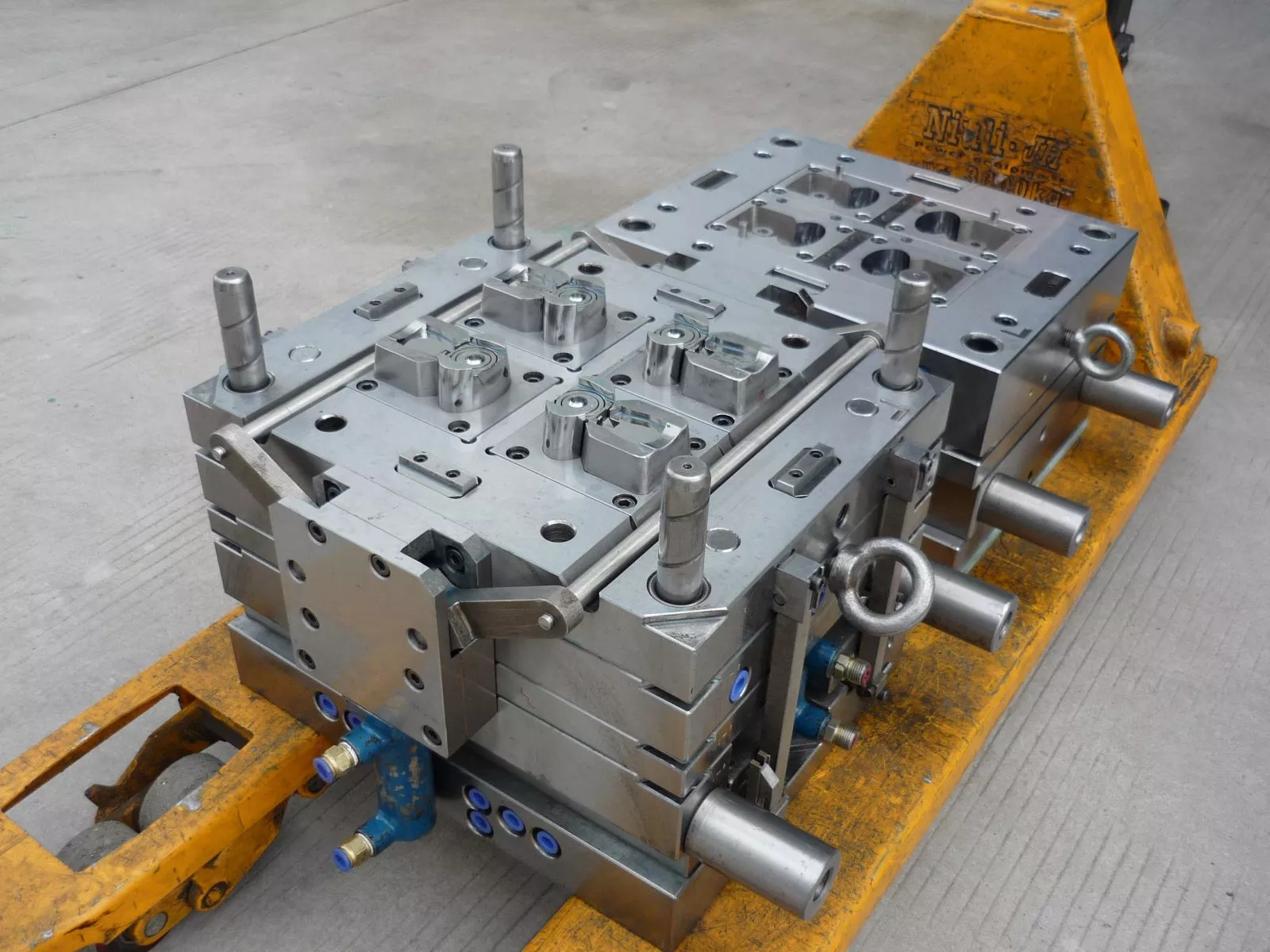

Maintenance Process of Injection Mold - Part One

1. First, the processing enterprise should equip each mold with a history card to record and count its use, care (lubrication, cleaning, rust prevention) and damage in detail, so as to find out which parts and components have been damaged and the degree of wear, which can provide information materials for finding and solving problems, as well as the molding process parameters and materials used for the mold, shortening the run time test of the mold and improve the production efficiency.

2. The processing enterprise should test various performances of the mold when the injection molding machine and mold are in normal operation, and measure the size of the finally formed plastic part. Through this information, the existing state of the mold can be determined, and the damage of cavity, core, cooling system and parting surface can be found out. According to the information from the plastic part, the damage state and maintenance measures of the mold can be judged.

3. It is necessary to focus on tracking and testing several important parts of the mold: the ejector and guide parts are used to ensure the opening and closing movement of the mold and the ejection of plastic parts. If any part is stuck due to damage, the production will be stopped. Therefore, the lubrication of the ejector pins and guide posts of the mold should be kept frequently (the most suitable lubricant should be selected), and whether the ejector pins and guide posts are deformed or damaged on the surface should be regularly checked. Once found, they should be replaced in time; after completing a production cycle, professional anti-rust oil should be coated on the working surface, moving and guiding parts of the mold. Also, special attention should be paid to the protection of the elastic strength of the bearing parts and spring molds with gears and racks to ensure that they are always in the best working state.

3. It is necessary to focus on tracking and testing several important parts of the mold: the ejector and guide parts are used to ensure the opening and closing movement of the mold and the ejection of plastic parts. If any part is stuck due to damage, the production will be stopped. Therefore, the lubrication of the ejector pins and guide posts of the mold should be kept frequently (the most suitable lubricant should be selected), and whether the ejector pins and guide posts are deformed or damaged on the surface should be regularly checked. Once found, they should be replaced in time; after completing a production cycle, professional anti-rust oil should be coated on the working surface, moving and guiding parts of the mold. Also, special attention should be paid to the protection of the elastic strength of the bearing parts and spring molds with gears and racks to ensure that they are always in the best working state.

2. The processing enterprise should test various performances of the mold when the injection molding machine and mold are in normal operation, and measure the size of the finally formed plastic part. Through this information, the existing state of the mold can be determined, and the damage of cavity, core, cooling system and parting surface can be found out. According to the information from the plastic part, the damage state and maintenance measures of the mold can be judged.

3. It is necessary to focus on tracking and testing several important parts of the mold: the ejector and guide parts are used to ensure the opening and closing movement of the mold and the ejection of plastic parts. If any part is stuck due to damage, the production will be stopped. Therefore, the lubrication of the ejector pins and guide posts of the mold should be kept frequently (the most suitable lubricant should be selected), and whether the ejector pins and guide posts are deformed or damaged on the surface should be regularly checked. Once found, they should be replaced in time; after completing a production cycle, professional anti-rust oil should be coated on the working surface, moving and guiding parts of the mold. Also, special attention should be paid to the protection of the elastic strength of the bearing parts and spring molds with gears and racks to ensure that they are always in the best working state.

3. It is necessary to focus on tracking and testing several important parts of the mold: the ejector and guide parts are used to ensure the opening and closing movement of the mold and the ejection of plastic parts. If any part is stuck due to damage, the production will be stopped. Therefore, the lubrication of the ejector pins and guide posts of the mold should be kept frequently (the most suitable lubricant should be selected), and whether the ejector pins and guide posts are deformed or damaged on the surface should be regularly checked. Once found, they should be replaced in time; after completing a production cycle, professional anti-rust oil should be coated on the working surface, moving and guiding parts of the mold. Also, special attention should be paid to the protection of the elastic strength of the bearing parts and spring molds with gears and racks to ensure that they are always in the best working state.Related News

- Design of Two-stage Overmolding for Automobile Headlight Cover

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part Two)

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part one)

- Design of the Upper Cover of a Household Air Conditioner Remote Control

- The Mold Cavity of Overmolding Handheld Forehead Thermometer Casing

- Overmolding Handheld Forehead Thermometer Shells

- Defects of Overmolded Lampshades

- An Introduction to Overmolding

- Overmolding Lampshades For Car Headlights

- Deformation of Plastic Components

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.