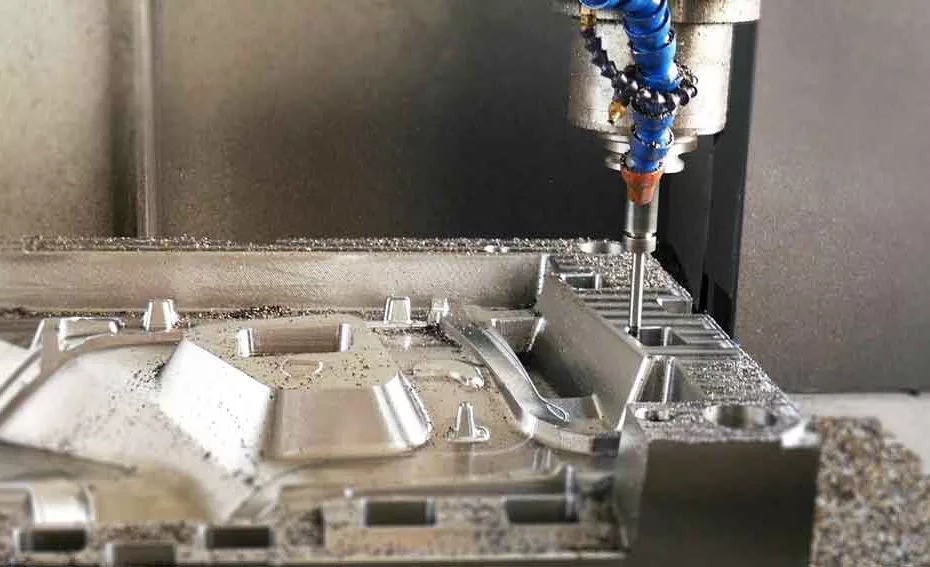

Plastic Mold Industry Develops to Meet New Demands

The development of plastic mould industry follows the development of plastic industry. In recent years, people have become more and more demanding on various equipment and articles with lightweight, beautiful appearance and good handfeel, which provides a broader market for plastic products. To develop plastic products, plastic molds must be developed accordingly.

Plastic molds account for more than 40% of the total number of molds, including large-scale injection molds for automobiles and household appliances, precision plastic molds for integrated circuits, multi-layer, multi-cavity, multi-material and multi-color precision injection molds for electronic information industry, machinery and packaging, plastic profile extrusion molds, pipe and nozzle molds for new building materials and water-saving agriculture. However, there is still a big gap between the current technical level of plastic molds and that of foreign countries. The total supply is also in shortage, with the annual import reaching several hundred million US dollars. Therefore, the "11th Five-Year Plan" period should focus on its development. Major users of plastic products such as automobiles, household appliances, office supplies, industrial electrical appliances, building materials and electronic communications have been operating at high levels and developing rapidly in recent years. Therefore, the plastic mold is also developing rapidly, and the plastic mold industry in our country is becoming larger and larger.

Molded parts of plastic mold show high precision, high complexity, high consistency, high yield and low consumption. The processing and manufacturing method of plastic mold has its unique creative value. Some experts in the industry think that the precision will be higher and higher as China's plastic mold industry becomes larger and larger. Ten years ago, the accuracy of precision molds was generally 5μm, and now it has reached 2 ~ 3 μ m. Soon, 1μm precision molds will be released to the market. With the miniaturization of parts and the improvement of precision, the tolerance of machining precision for some plastic molds is required to be less than 1μm, which requires the development of ultra-precision machining.

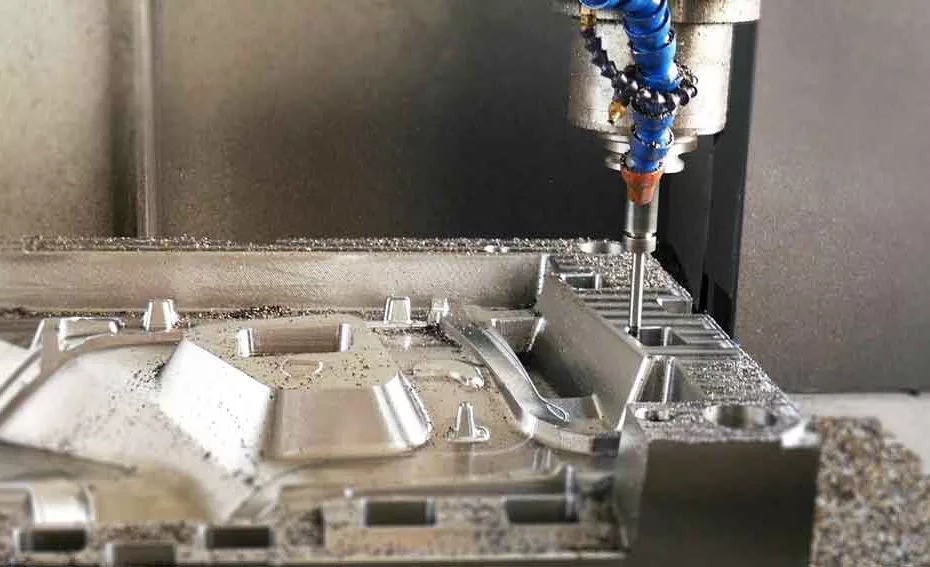

Experts believe that China's plastic mold industry needs to further develop multi-functional composite molds. A set of multi-functional molds not only punch and form parts, but also undertake assembly tasks such as stacking, tapping, riveting and locking. Multi-color and multi-material plastic forming dies will also develop rapidly. This kind of plastic mold shortens the production cycle of products and will be developed and applied in different fields in the future.

With the popularization and application of hot runner technology, the proportion of hot runner mold in plastic mold in China will gradually increase. The plastic mold using hot runner technology can improve the yield and quality of the parts, and can also save the raw materials of the parts. The application of this technology has developed rapidly in foreign countries. Hot runner molds have also been produced domestically. Some enterprises have reached about 30%, but overall, the proportion is still very low and needs to be developed urgently.

Chinese plastic mold experts believe that the proportion of die casting moulds in the plastic mold industry will continue to improve. With the development of products such as vehicles and motors towards lightweight, more and more requirements will be put forward for the number, service life and complexity of die casting moulds. With the development of replacing steel and with plastic and the continuous improvement of precision and complexity of product parts, the proportion of plastic moulds will continue to improve, and the precision and complexity will also follow the corresponding progress.

Plastic molds account for more than 40% of the total number of molds, including large-scale injection molds for automobiles and household appliances, precision plastic molds for integrated circuits, multi-layer, multi-cavity, multi-material and multi-color precision injection molds for electronic information industry, machinery and packaging, plastic profile extrusion molds, pipe and nozzle molds for new building materials and water-saving agriculture. However, there is still a big gap between the current technical level of plastic molds and that of foreign countries. The total supply is also in shortage, with the annual import reaching several hundred million US dollars. Therefore, the "11th Five-Year Plan" period should focus on its development. Major users of plastic products such as automobiles, household appliances, office supplies, industrial electrical appliances, building materials and electronic communications have been operating at high levels and developing rapidly in recent years. Therefore, the plastic mold is also developing rapidly, and the plastic mold industry in our country is becoming larger and larger.

Molded parts of plastic mold show high precision, high complexity, high consistency, high yield and low consumption. The processing and manufacturing method of plastic mold has its unique creative value. Some experts in the industry think that the precision will be higher and higher as China's plastic mold industry becomes larger and larger. Ten years ago, the accuracy of precision molds was generally 5μm, and now it has reached 2 ~ 3 μ m. Soon, 1μm precision molds will be released to the market. With the miniaturization of parts and the improvement of precision, the tolerance of machining precision for some plastic molds is required to be less than 1μm, which requires the development of ultra-precision machining.

Experts believe that China's plastic mold industry needs to further develop multi-functional composite molds. A set of multi-functional molds not only punch and form parts, but also undertake assembly tasks such as stacking, tapping, riveting and locking. Multi-color and multi-material plastic forming dies will also develop rapidly. This kind of plastic mold shortens the production cycle of products and will be developed and applied in different fields in the future.

With the popularization and application of hot runner technology, the proportion of hot runner mold in plastic mold in China will gradually increase. The plastic mold using hot runner technology can improve the yield and quality of the parts, and can also save the raw materials of the parts. The application of this technology has developed rapidly in foreign countries. Hot runner molds have also been produced domestically. Some enterprises have reached about 30%, but overall, the proportion is still very low and needs to be developed urgently.

Chinese plastic mold experts believe that the proportion of die casting moulds in the plastic mold industry will continue to improve. With the development of products such as vehicles and motors towards lightweight, more and more requirements will be put forward for the number, service life and complexity of die casting moulds. With the development of replacing steel and with plastic and the continuous improvement of precision and complexity of product parts, the proportion of plastic moulds will continue to improve, and the precision and complexity will also follow the corresponding progress.

Related News

- Design of Two-stage Overmolding for Automobile Headlight Cover

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part Two)

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part one)

- Design of the Upper Cover of a Household Air Conditioner Remote Control

- The Mold Cavity of Overmolding Handheld Forehead Thermometer Casing

- Overmolding Handheld Forehead Thermometer Shells

- Defects of Overmolded Lampshades

- An Introduction to Overmolding

- Overmolding Lampshades For Car Headlights

- Deformation of Plastic Components

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.