The Stamping Equipment and Process

Stamping equipment includes punches, feeders, unloaders, receivers and CCD (online image detection systems).

(1) Punches

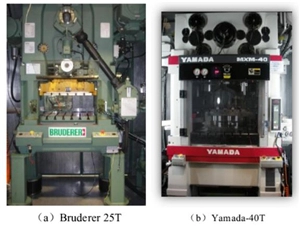

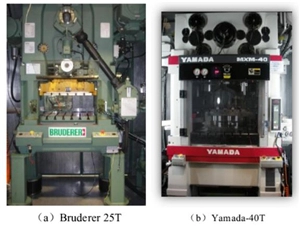

High-speed punches represent the most advanced technology in the world, which adopts high-impact design to eliminate stress in production and ensure high precision in long-term production. The three-circle guide post is designed with a forced lubrication system to obtain the best motion accuracy of the slide, thereby reducing dynamic friction to the lowest extent and minimizing thermal deformation. The mold's height indicator and slider hydraulic locking device can keep the mold height constant and ensure the product's accuracy. A microcomputer controller is used to control the operating angle of the punch, rotation speed during production and location of the fault, so that this information is displayed on the independent console. You first need to choose a good high-speed precision punch to achieve the purpose of high-speed production and stable quality. A good precision punch should have the following features: perfect machine balance systems, excellent performance of adjustable strokes, suitable punching force, speed ranges from 100 to 1500 times/min. The equipment we selected is shown in Figure 1.

Figure 1 The punch

(2) Feeders

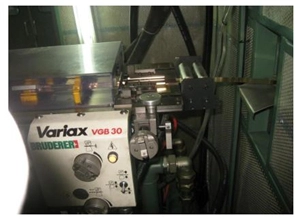

An efficient feeder can realize the ideal connection between the punch and die, and it must be able to ensure absolute step accuracy. This is the basis for ensuring the production of high-quality stamping parts. It is no longer possible to rely solely on the positioning pins in the mold, especially for the high stamping speed. A feeder with precise step length must be used to jointly ensure the accuracy of the step distance. We chose the VGB clip feeder, as shown in figure 2.

Figure 2 Feeders

(3) Feeding machines

We use a disc feeding machine as shown in figure 3. Its working principle is that the raw material is placed on a disc with a diameter of 1300 mm. Driven by external traction, the travel button will automatically be on and the motor will start. The disc will rotate around the vertical axis, and the rotating speed can be adjusted. The advantages of a disc feeding machine are that the power of the feeding machine adopts imported motors, which has the advantages of low noise, high efficiency and durability. The speed of the turntable can be adjusted, and it has the function of clockwise and anticlockwise rotations. When the operator finds that the rotation of the raw materials is reversed, he only needs to select the clockwise and anticlockwise button in the control box to adjust the required direction, so that the material doesn't need to be loaded again and the released material can be reversely recycled, reducing the labor force.

Figure 3 Feeding machines

(4) Receiving machines

We adopt a PS vertical receiving machine as shown in figure 4. If the punching speed is 1000 times per minute and one roll needs 30,000 terminals, one roll can be produced every 30 minutes. At this time, the automatic receiving machine is especially important. It must be able to automatically count, cut, and change the material disc. Manpower alone cannot handle a lot of output timely.

Figure 4 Receiving machines

(5) Soundproof covers

The stamping noise generated in the high-speed stamping process is very great, which has a great impact on the environment of the entire workshop and the operator, so the soundproof cover is very necessary. The soundproof cover is shown in figure 5.

Figure 5 Soundproof covers

(6) Image detectors

Usually, when there is no image detector, random inspection is required at regular intervals or every few rolls of terminals to prevent a large amount of waste. However, in high-speed stamping, the size has not been detected, and hundreds of thousands of terminals may have been produced. Once there is a size deviation, a large number of waste products may be produced. A set of image detectors can detect the size of each terminal (usually an important and easily changed size). Once the size is out of specification, the image detector will immediately alarm and shut down. We use a high-precision detection device CCD, as shown in figure 6.

Figure 6 CCD 100% online inspection equipment

Stamping

The cold stamping gradually adopts mechanization and automation. In order to meet the needs of mass production, the stamping equipment has been developed from a single-station low-speed punch to a multi-station high-speed punch. On the high-speed punch, a multi-station progressive die is used for stamping, making cold stamping obtain highly automated. For example, automobile covering parts can be produced on an assembly line with automatic feeding, automatic pickup, and automatic transmission.

The use of new stamping processes such as fine blanking, hydroforming, stamping-welding composite technology and other special stamping processes further expands the application range of stamping, greatly improves the quality and production efficiency of stamped parts, and further reduces production costs.

Now, there is an unprecedented consensus on the importance of the development of advanced manufacturing technology. The technology of stamping has made unprecedented great progress not only in deepness but also in scopes. It not only has the characteristics of combining with high and new technology, but also great changes have also taken place in the system. The stamping field also involves information technology, computer technology and modern measurement and control technology, thereby promoting the formation and development of existing advanced stamping technology.

(1) Punches

High-speed punches represent the most advanced technology in the world, which adopts high-impact design to eliminate stress in production and ensure high precision in long-term production. The three-circle guide post is designed with a forced lubrication system to obtain the best motion accuracy of the slide, thereby reducing dynamic friction to the lowest extent and minimizing thermal deformation. The mold's height indicator and slider hydraulic locking device can keep the mold height constant and ensure the product's accuracy. A microcomputer controller is used to control the operating angle of the punch, rotation speed during production and location of the fault, so that this information is displayed on the independent console. You first need to choose a good high-speed precision punch to achieve the purpose of high-speed production and stable quality. A good precision punch should have the following features: perfect machine balance systems, excellent performance of adjustable strokes, suitable punching force, speed ranges from 100 to 1500 times/min. The equipment we selected is shown in Figure 1.

Figure 1 The punch

(2) Feeders

An efficient feeder can realize the ideal connection between the punch and die, and it must be able to ensure absolute step accuracy. This is the basis for ensuring the production of high-quality stamping parts. It is no longer possible to rely solely on the positioning pins in the mold, especially for the high stamping speed. A feeder with precise step length must be used to jointly ensure the accuracy of the step distance. We chose the VGB clip feeder, as shown in figure 2.

Figure 2 Feeders

(3) Feeding machines

We use a disc feeding machine as shown in figure 3. Its working principle is that the raw material is placed on a disc with a diameter of 1300 mm. Driven by external traction, the travel button will automatically be on and the motor will start. The disc will rotate around the vertical axis, and the rotating speed can be adjusted. The advantages of a disc feeding machine are that the power of the feeding machine adopts imported motors, which has the advantages of low noise, high efficiency and durability. The speed of the turntable can be adjusted, and it has the function of clockwise and anticlockwise rotations. When the operator finds that the rotation of the raw materials is reversed, he only needs to select the clockwise and anticlockwise button in the control box to adjust the required direction, so that the material doesn't need to be loaded again and the released material can be reversely recycled, reducing the labor force.

Figure 3 Feeding machines

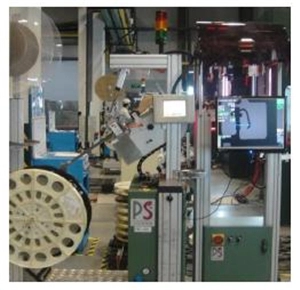

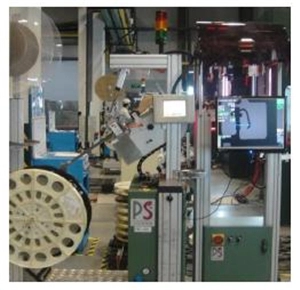

(4) Receiving machines

We adopt a PS vertical receiving machine as shown in figure 4. If the punching speed is 1000 times per minute and one roll needs 30,000 terminals, one roll can be produced every 30 minutes. At this time, the automatic receiving machine is especially important. It must be able to automatically count, cut, and change the material disc. Manpower alone cannot handle a lot of output timely.

Figure 4 Receiving machines

(5) Soundproof covers

The stamping noise generated in the high-speed stamping process is very great, which has a great impact on the environment of the entire workshop and the operator, so the soundproof cover is very necessary. The soundproof cover is shown in figure 5.

Figure 5 Soundproof covers

(6) Image detectors

Usually, when there is no image detector, random inspection is required at regular intervals or every few rolls of terminals to prevent a large amount of waste. However, in high-speed stamping, the size has not been detected, and hundreds of thousands of terminals may have been produced. Once there is a size deviation, a large number of waste products may be produced. A set of image detectors can detect the size of each terminal (usually an important and easily changed size). Once the size is out of specification, the image detector will immediately alarm and shut down. We use a high-precision detection device CCD, as shown in figure 6.

Figure 6 CCD 100% online inspection equipment

Stamping

The cold stamping gradually adopts mechanization and automation. In order to meet the needs of mass production, the stamping equipment has been developed from a single-station low-speed punch to a multi-station high-speed punch. On the high-speed punch, a multi-station progressive die is used for stamping, making cold stamping obtain highly automated. For example, automobile covering parts can be produced on an assembly line with automatic feeding, automatic pickup, and automatic transmission.

The use of new stamping processes such as fine blanking, hydroforming, stamping-welding composite technology and other special stamping processes further expands the application range of stamping, greatly improves the quality and production efficiency of stamped parts, and further reduces production costs.

Now, there is an unprecedented consensus on the importance of the development of advanced manufacturing technology. The technology of stamping has made unprecedented great progress not only in deepness but also in scopes. It not only has the characteristics of combining with high and new technology, but also great changes have also taken place in the system. The stamping field also involves information technology, computer technology and modern measurement and control technology, thereby promoting the formation and development of existing advanced stamping technology.

Related News

- Design of Two-stage Overmolding for Automobile Headlight Cover

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part Two)

- Research on Stamping of Complex Aerospace Sheet Metal Components (Part one)

- Design of the Upper Cover of a Household Air Conditioner Remote Control

- The Mold Cavity of Overmolding Handheld Forehead Thermometer Casing

- Overmolding Handheld Forehead Thermometer Shells

- Defects of Overmolded Lampshades

- An Introduction to Overmolding

- Overmolding Lampshades For Car Headlights

- Deformation of Plastic Components

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.