The Stamping Industry

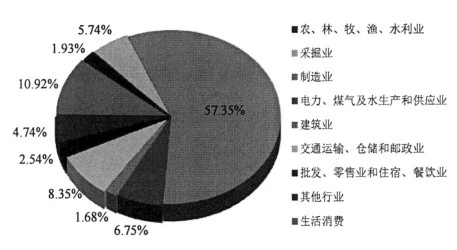

Under the background of global warming, the low-carbon economy mode based on low energy consumption and low pollution has attracted the attention of all countries in the world, and low-carbon development has also become an inevitable trend of current social development. With the convening of the Copenhagen Climate Change Conference, "low carbon economy" has come into people's field of vision, and at the same time, countries around the world have reached a consensus on the development of a low carbon economy. Each country has issued a series of legal documents and formulated relevant emission reduction targets. For example, the US Clean Energy Act stipulates that the use of fossil fuels should be controlled. By 2020, the emission of GHG gas should be 17% lower than that in 2005, and 53% lower by 2050. In the low-carbon transformation plan, the United Kingdom proposed that enterprises should maximize the development opportunities brought by the low-carbon economy, and ensure the coordinated distribution of the overall economy, resources and benefits in the process of economic transformation. The German Ministry of Environment has published a strategic document for the development of a low-carbon economy, emphasizing the low-carbon economy as a guideline for economic modernization. The emission reduction target proposed by Japan in the "Fukuda Blueprint" is that by 2050, Japan's GHG gas emissions will be reduced by 60% to 80% compared with 2009, and the proportion of "zero-pollution power supply" in the total power generation will exceed 50%. In China, "By 2020, China's GHG gas emissions per unit of GDP will be reduced by 40% compared with 2005. 45% has been incorporated into the long-term plan for China's national economic and social development as a binding indicator. Manufacturing is the pillar industry of China's national economic development, and its industrial added value accounts for 35% of the gross national product (GDP). However, with the rapid development of the global economy, the demand for energy and resources in the manufacturing industry is increasing rapidly. The energy consumption of various industries in China in 2013 is shown in Figure 1, the proportion of energy consumption in the manufacturing industry reached 57%, which is the major source of carbon emissions in China. Therefore, to achieve China's emission reduction target in 2020, low-carbon manufacturing must be carried out. It is the main way to achieve the purpose of carbon emission reduction in China's manufacturing industry, and it is an important way for China to cope with the current climate warming, the development of a circular economy, and the implementation of energy conservation and emission reduction. It is of great significance for China to develop a low-carbon economy and achieve the strategic development goals of transformation and upgrading of the manufacturing industry.

Figure 1 Energy consumption of various industries in China in 2013

The stamping industry is an important part of the metal processing industry and the basic industry in the machinery manufacturing industry. 60 to 70% of the steel used in China's manufacturing industry is sheet metal, most of which are used for stamping. Compared with other processing methods, stamping is an advanced processing method with high production efficiency, fewer chips or no cutting; stamping has high production efficiency and easy operation; stamping is easy to realize mechanization and automation. Stamping products are widely used in automotive, aerospace, electrical and electronic industries due to their high strength, low consumption of raw materials and other advantages. With the rapid development of modern industry, the variety of metal plate stamping parts is increasing and the demand is also increasing, which has played an important role in the field of industrial manufacturing. For example, the proportion of stamping parts in automobile parts exceeds 75%, and its proportion in aircraft parts is more than 50%. However, in the stamping process, the long production line, many steps in the stamping process, unreasonable selection and use of the forming equipment will cause energy waste in the stamping process. Taking automobile manufacturing as an example, in the stamping workshop, the production cycle is limited due to the unreasonable design of the process, so that the motor in the stamping equipment works at a low load of about 25% for a long time, resulting in a lot of energy waste. It can be seen that the energy waste in the stamping process has become a key factor affecting the production cost and production efficiency of products, which not only directly affects the economic interests of enterprises, but also restricts the pace of China's development to an intensive society. Therefore, it is extremely urgent to carry out low-carbon energy saving in the stamping industry, improving the energy utilization rate of the stamping industry, playing an important role in promoting energy conservation and emission reduction, improving economic benefits, promoting the transformation and upgrading of the stamping industry and sustainable and healthy development, and realizing "Made in China 2025".

In view of the serious energy waste in the forming process and the high energy consumption and low efficiency of forming equipment currently faced in the stamping industry, the main shortcomings of the current stamping process and equipment are revealed by analyzing the manufacturing characteristics and energy consumption characteristics of the stamping process. The corresponding energy-saving optimization method can not only provide a feasible energy-saving scheduling scheme for the production scheduling personnel of the enterprise, but also improve the production efficiency of the enterprise, energy-saving technology and management level of the enterprise.

At the same time, by analyzing the structural design and control methods of the forming equipment in the stamping process, the existing shortcomings can provide a reference and basis for the low-carbon optimization of the structure and control of the subsequent hydraulic press and other forming equipment. In addition, the implementation of low-carbon manufacturing in the stamping industry is in line with the basic strategy of sustainable development in China, which has played a powerful role in promoting the promotion and application of the concepts of green, low-carbon and sustainable manufacturing in enterprises.

Related News

- Response Strategies for Rapid Prototyping of Metal in the Mechanical Manufacturing

- Applications and Challenges of Rapid Prototyping in Micro-Machining Manufacturing

- Rapid Prototyping of Metals in Mechanical Manufacturing

- Quality Control for the Injection Molding of Automotive Interior Parts

- Solutions to Defects in Injection Molding of Automotive Interior Parts

- The Glossiness of Injection Molded Products

- Painting Injection Molding Parts

- How to Distinguish Various Types of Plastics?

- Characteristics of Plastics

- The Stamping Industry

Services

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.